Refinery / Petro-Chemicals

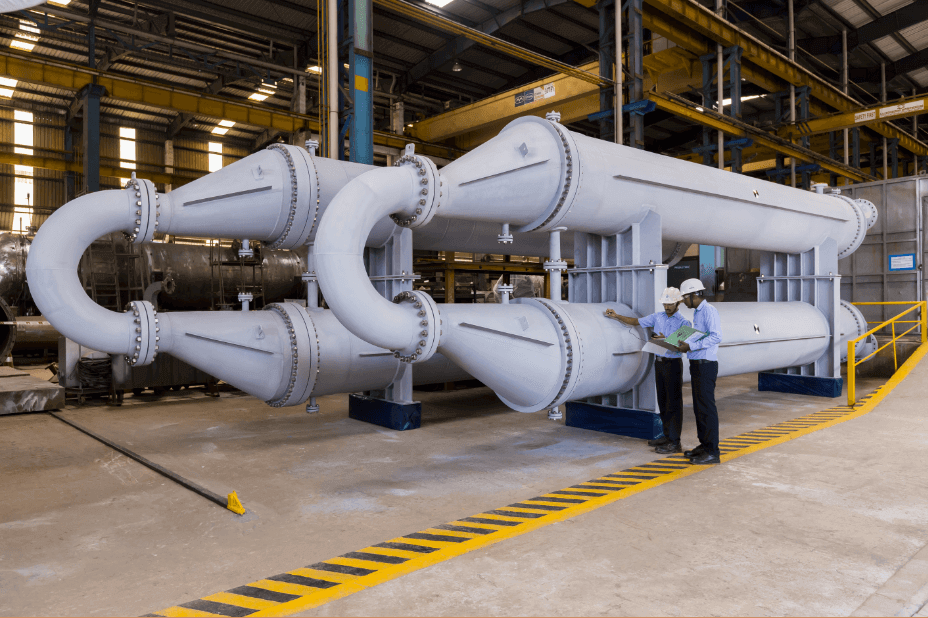

Our Process Equipments mainly Shell & Tube Heat Exchangers, Vessels, Reactors & Columns are successfully running in the global Oil fields. Our supply reference includes the units such as CDU, VDU, NHT, DHT, SRR, FCC, SRU, MS Block and Isomerization units etc. The types of Heat Exchangers supplied to Oil Refineries are Shell and Tube Heat Exchangers with stationary tubesheet, Floating head Heat Exchangers, Helix type Heat Exchangers, Reboilers, Boilers, Refrigerant condensers, Vacuum condensers, Evaporators, Pipe-in-Pipe Heat Exchangers, Hair Pin Exchangers, Rod Baffle Exchangers, High Pressure Exchangers etc,.

Fertilizer

We have rich experience in supplying many High Pressure & Critical Exchangers to Fertilizer plants for Urea, Ammonia Units under their respective Process Liscensors. Our product range comprises of Reactors, Vessels, Heat Exchangers and equipment for various services including high-pressure, high-temperature and hydrogen service. Major equipment supplied includes process gas waste heat boilers, steam drums and super heaters, Urea reactors, Carbamate Condensers, Urea Strippers, Ammonia Converters, CO2 Absorber, Regenerators, HP / LP Flash Drums and a range of high pressure heat exchangers and pressure vessels.

Energy Sector

Our contribution to the Energy & Power sectors includes supply of Heat Exchangers to Power Plants, Solar Applications etc., Recently, we supplied Shell & Tube Exchangers to Advanced Compressed Air Energy Storage Technology in which electricity is generated from compressed air.

We have also supplied major heat transfer equipment like Boiler Feed Water Pre-Heaters, Boiler Headers, Steam Drums, Air Cooled Condensers, Header Boxes etc., We can supply Steam Generators, Deaerators and Surface Condensers for the Concentrated Solar Thermal Power Plants. For the Solar Power Plants with Molten Salt based Thermal Storage facility, we can design and manufacture Molten Salt/HTF heat exchangers.

The company also has capabilities to manufacture Feed Water Heaters which are used for heating the Boiler Feed water using the Intermediate/High pressure steam from the LP/HP stages of steam turbines. Our Feed Water Heaters are designed taking into account the three heat transfer zones namely de-superheating, condensing and sub-cooling. At Precision manufacturing of the heaters are at ease due to the availability of BTA drilling machines for drilling tubesheet thickness as high as 500 mm.