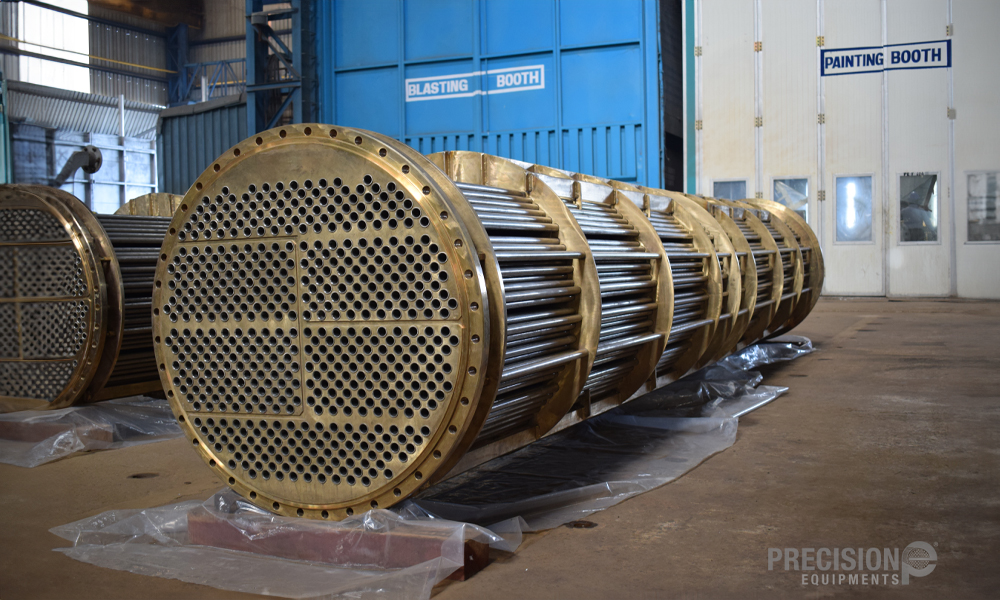

Shell and Tube Heat Exchangers

Our Shell & Tube Heat Exchangers are widely used in refineries, petrochemical plants, fertilizer units, chemical plants, and a broad range of process industries worldwide. Designed for parallel flow, counterflow, and crossflow arrangements, these exchangers are engineered to perform reliably under critical operating conditions.

Since our shell & tube heat exchangers are designed and manufactured with precision, they have been working at various sites worldwide without any issues, with performance or operational and maintenance.

We specialize in advanced configurations such as Helical Baffle, Rod Baffle, and Low-Fin designs. With comprehensive in-house capabilities to design and manufacture all TEMA types, we provide both standard and highly critical Shell & Tube Heat Exchangers customized to meet specific process requirements