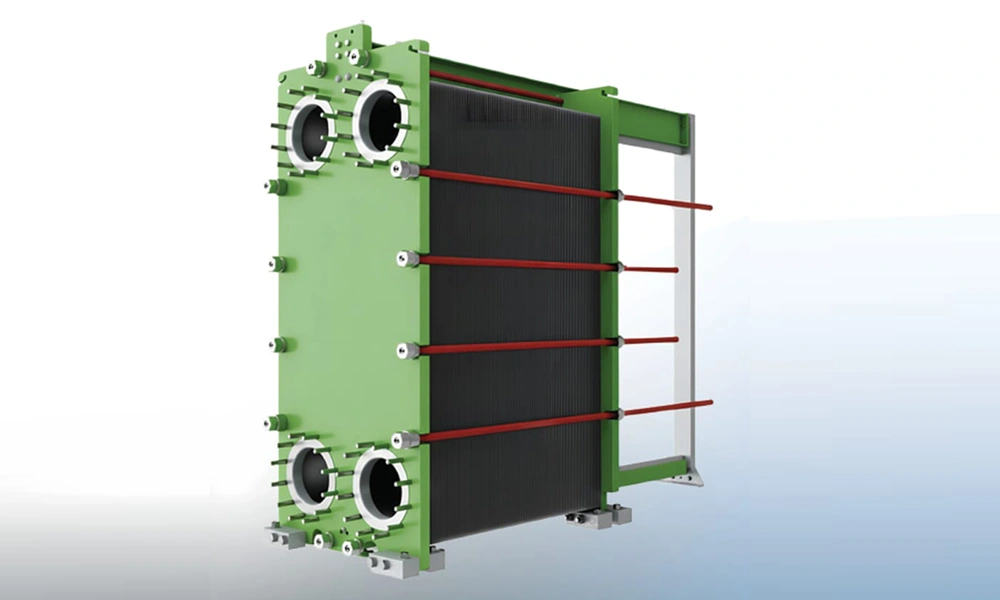

Plate & Frame Heat Exchanger

Precision Plate & Frame Heat Exchangers are engineered to deliver exceptionally high thermal efficiency, reliability, and long service life in a compact and flexible design.

The system consists of a series of precision-pressed corrugated plates arranged in a frame, creating highly turbulent flow paths that maximize heat transfer while minimizing fouling.

The chevron plate pattern ensures uniform flow distribution and enhanced heat transfer coefficients, allowing efficient operation even with small temperature approaches. The modular plate design enables easy expansion or capacity modification by simply adding or removing plates, making it a future-ready solution for evolving process requirements.

Designed for demanding industrial environments, Precision PHEs support a wide range of plate materials (SS 304, SS 316, SMO 254, Hastelloy C-276, Titanium Gr 1 / Gr 11) and gasket materials (NBR, EPDM, Viton), ensuring compatibility with corrosive and high-purity fluids. Units are capable of operating up to 180 °C and 30 bar(g).