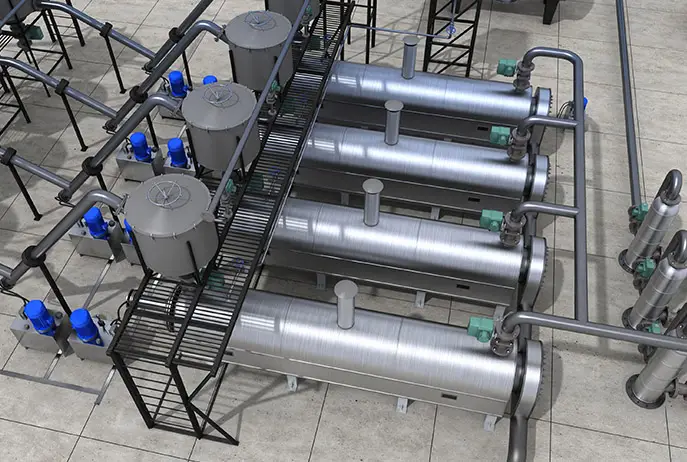

Engineering

Capability is not just what we do. It’s how we think. With in-depth design expertise, advanced engineering tools, and strict adherence to global standards, we build process equipment that performs, lasts, and leads across industries.

Thermal Design

At Precision, we are strongly committed to supporting our customers from the very early phase of the projects. Our design engineers are actively involved in the thermal design of heat-exchanging equipment. With deep process knowledge and expertise in process simulation, we are able to select the right technology for each application and custom-design every piece of equipment. This enables us to deliver the most efficient and cost-effective configurations. Our thermal team supports all the technologies in our portfolio.

Products

Our heat transfer specialists are equipped to design and rate:

- Any conventional TEMA-type Shell & Tube Heat Exchangers

- High-pressure Heat Exchangers

- Hairpin-type Heat Exchangers

- Pressure Vessels & Reactors

We also have expertise in manufacturing Helical Baffle and Rod Baffle Heat Exchangers.

Software

At Precision, we use widely recognised software:

We use globally recognised and industry-standard software to ensure precision in every stage of thermal and mechanical design. These tools help us simulate, analyse, and optimise equipment performance, allowing for efficient, reliable, and cost-effective engineering solutions customised to process requirements. This digital integration ensures consistency, accuracy, and agility across every phase of our design workflow.

Thermal Calculations

- Xchanger Suite Package powered by HTRI

- Aspen Shell & Tube Exchanger

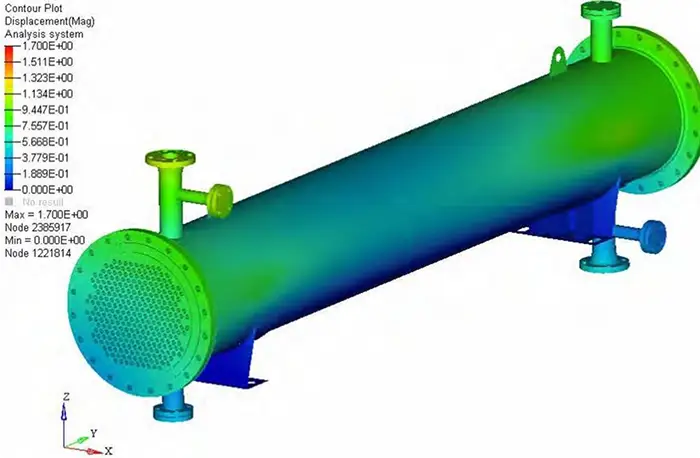

CFD Analysis

- ANSYS

Mechanical

We have in-house capability for mechanical design & preparation of detailed fabrication drawings. Over a period of 40 years, the company has also developed many in-house tools for designing certain aspects which are not covered in commercially available software. The output is a clear and detailed fabrication drawing which captures all the customer’s requirements, including their specific quality requirements.

The design department also works closely with all the other departments so that if there are any post-order changes, the same gets captured and communicated through the system without any loss of information.

Software

Mechanical Design :

Analysis:

Materials

Codes & Standards

We adhere to globally recognised codes and standards, ensuring compliance, safety, and performance across all our designs and manufacturing. Our expertise spans ASME, EN, IBR, API, TEMA, HEI, and more to meet diverse regulatory requirements.

Codes & Standards

- ASME Sec. VIII Div. 1

- ASME Sec. VIII Div. 2

- API-660

- API-661

- PD-5500

- AS-1210 – AUS

- TEMA 10th Edition

- EN 13445 (PED Directive) – EU

- IBR

- PED

- HEI

Standards :

- API

- TEMA

- HEI

Get Efficient Solutions for Your Industrial Needs.

Looking for dependable, high-performance solutions? Let’s talk. We’ll help you find the right equipment for your industrial needs, built with precision and designed to keep your operations running smoothly.